Three Types of Mitre Saw

These power tools are ideal for cutting planks, window trims, and crown mouldings as well as creating bevelled edges for door and picture frames.

The three types of mitre saws are:

Standard: This is a basic drop saw capable of making straight crosscuts and mitre cuts. For straight cuts, it plunges at a 90-degree angle into wood pieces. For mitre cuts, its blade enters the wood at lateral angles up to 45 degrees. While its capabilities are like the regular handsaw and manual mitre box previously used for these cuts, standard mitre saws provide the power, speed, accuracy, and convenience of power saws. They’re ideal for cutting baseboards and completing framing tasks.

Compound: Unlike a standard model, the blade and head of this tool can rotate to the side. It’s capable of making compound cuts (both mitre and bevel cuts) in addition to regular cross and mitre cuts. When buying a mitre saw in this category, you have two choices: single-bevel and dual-bevel models. The blade/head of a single-bevel unit can rotate to either the left or right side of the saw. This design allows it to make bevel and mitre cuts at varying angles. High-end models can tilt up to 50 degrees. Dual compound-mitre saws offer greater flexibility by having blades that tilt in both directions. With these, woodworkers can make bevel and compound cuts in both directions without flipping their workpieces.

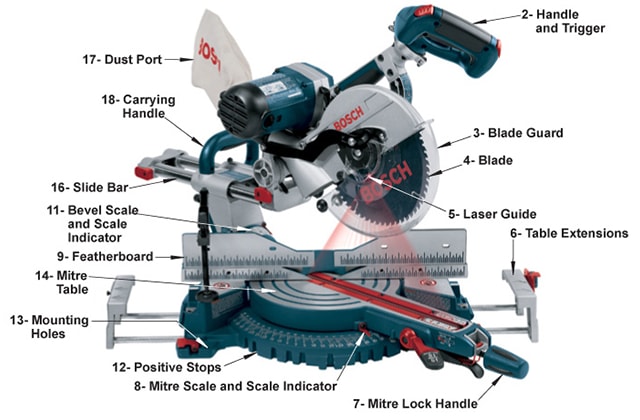

Sliding Compound: This offers all the benefits of a compound model and adds a few advanced mitre saw features. The most important one is a sliding saw head. The motor and blade assembly mounts on a sliding rail that moves back and forth. This movable arm allows the saw to accommodate longer and wider wood pieces. It’s also available in single- and dual-bevel models.